Pacific Post and Beam entered three tenons in the Tenon Testing at the 2012 Western Timber Framer’s Guild conference. The tenon pictured above was the third entry, the only one of all the entries that did not get torn apart!

The joint was made with (4) 10 inch long by 1 inch diameter fiberglass rods epoxied into the wood. Though this is not traditional timber framing, we have used similar connections in the past.

Incredibly, there was very little deformation while under a 40,000 lbs load! The surfaces may have pulled about 1/8″ apart. The test was stopped because the limits of the equipment had been reached. There were also safety concerns for the spectators and their beers.

Category Archives: Interest

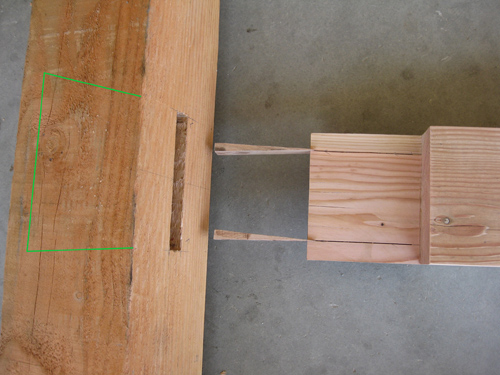

Wedged Tenon with Block

Pacific Post and Beam entered three tenons in the Tenon Testing at the 2012 Western Timber Framer’s Guild conference. The tenon pictured above was the second entry, a shaped tenon with a wedge/block. The tenon is inserted into the mortise. (The shape of the mortise is drawn on the side of the beam) The dovetail side of the tenon is then shifted to the side of the mortise with the matching shape. Everything is held in place by inserting an oak wedge/block.

The dovetail side of the tenon sheared off parallel to the wood grain. This connection held close to 8000 lbs before the tenon was pulled out of the mortise.

Next week we’ll post the connection that held 40,000 lbs before the engineers stopped the testing because the capacity of the equipment had been exceeded!

Tenon Testing: Blind Wedge Tenon

Pacific Post and Beam entered three tenons in the Tenon Testing at the 2012 Western Timber Framer’s Guild conference. The tenon pictured above was a tenon with blind wedges. As the tenon approached the bottom of the dovetail shaped mortise, the wedges were forced into the tenon deforming it into the shape of the mortise. This connection held close to 5000 lbs before the tenon was pulled out of the mortise.

The interesting part of this failure was the was how the sides of the tenon failed differently. The grain of the wood on one side of the tenon was essentially vertical-grain between the wedge and the mortise wall verses the other side which was side-grain. You can see that the side-grain example compressed, whereas the vertical-grain did not.

We will post the other two examples we entered soon.